US & Asia-Pacific +1 800 764 0366 | Europe & Middle East +44 (0)115 980 3800

News:

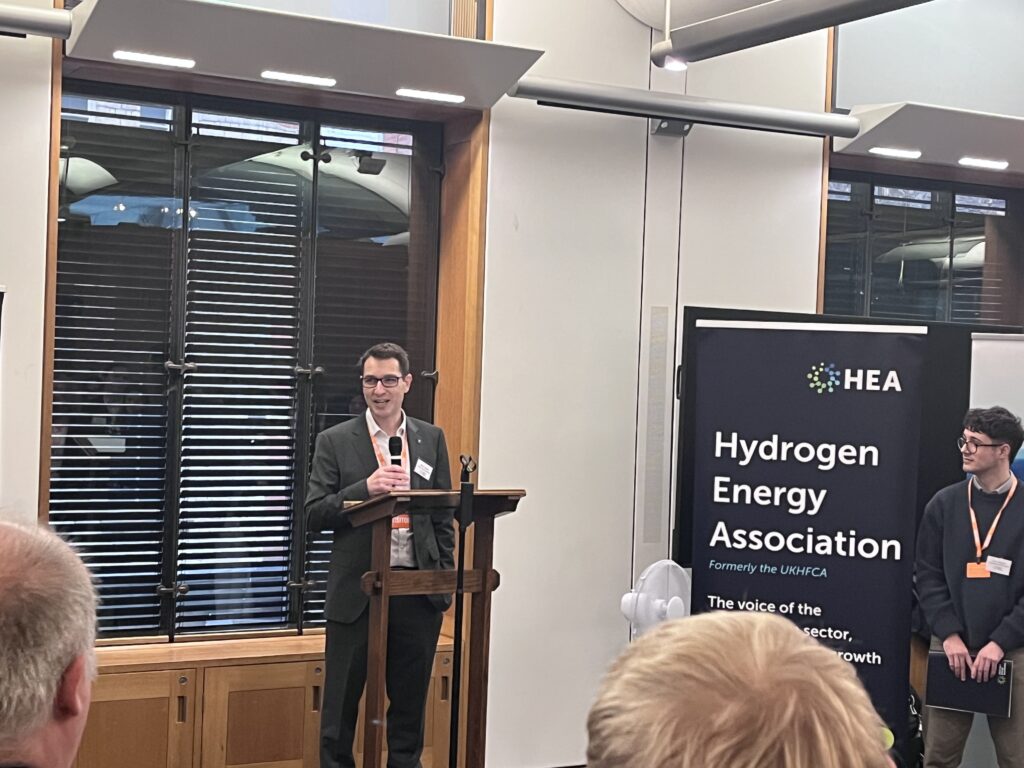

Policy certainty essential to unlock UK hydrogen demand, says Luxfer Gas Cylinders at Hydrogen Energy Association’s Parliamentary launch

A pivotal moment for the UK's energy future, Luxfer's Mark Lawday tells Westminster audience at 'State of the Hydrogen Nation' event.

Building confidence in delivery is a decisive factor in unlocking the UK’s hydrogen economy, stated Mark Lawday, Vice President of Luxfer Gas Cylinders, as he addressed innovators, policymakers and industry leaders at a Westminster launch this week.

Organised by the Hydrogen Energy Association (HEA), the Parliamentary event marked the unveiling of its ‘State of the Hydrogen Nation’ report, which revealed that demand is now the key factor holding back the industry, rather than hydrogen production capacity.

Mark Lawday addressed guests including MPs and civil servants, stating that while the UK has “the skills, manufacturing base and innovation to lead in hydrogen”, progress now depends on coordinated, predictable delivery that gives businesses the certainty to invest, scale and commit long‑term capital.

He said: “To unlock the full potential of hydrogen, industry needs confidence. Confidence that the UK hydrogen economy will be supported to grow consistently and predictably.

"Policy certainty will allow companies, like Luxfer Gas Cylinders, to keep investing. That means expanding our manufacturing at our UK sites, bringing more cylinder production here, strengthening our supply chains and creating more jobs in our local communities.”

Mark’s comments echo the report’s central finding that demand — not supply — is now the biggest constraint on deployment, with 81% of organisations seeking offtakers saying demand is difficult to secure, and 60% of potential end‑users finding hydrogen hard to integrate.

Drawing on more than 25 years in hydrogen systems engineering, Mark outlined how Luxfer engineers developed the first 700‑bar composite cylinders in the sector, and has since pioneered high‑pressure storage, modular transport systems, alongside ‘virtual pipeline’ solutions.

In his speech, Mark highlighted how, as the UK scales hydrogen production through upcoming allocation rounds, the ability to move hydrogen safely from where it’s produced to where it’s needed becomes fundamental to market growth. It’s a gap the HEA report also identifies as a key barrier to Final Investment Decisions.

Responding directly to this challenge, Luxfer’s UK engineering team developed the transformational G-Stor® Hydrosphere – a 40‑ft MEGC system capable of transporting around one tonne of hydrogen using fewer cylinders and connections, improving efficiency and reducing operational complexity.

And the organisation is continuing to innovate. Mark added: “Across our Nottingham and Manchester facilities, Luxfer Gas Cylinders employs around 600 colleagues, with roughly 10% working on hydrogen programmes spanning electrolysis coatings, high‑pressure storage, mobility systems and bulk transport solutions.

“We’ve produced thousands of hydrogen-powered fuel systems, including marine vessels, ground equipment, construction vehicle, trucks - and buses that are journeying across the streets of London as we speak. These projects demonstrate what’s possible when innovation is matched with forward-looking and consistent policy – so that’s what we ask of government today.”

Luxfer Gas Cylinders was a sponsor of the launch event for the HEA’s State of the Hydrogen Nation report on Tuesday 27 January 2026. The study also revealed:

- - 84% of organisations expect their UK hydrogen investment to increase or remain stable in the next 12 months.

- - With current policy, 3,800 UK hydrogen jobs are expected by 2030.

- - With greater certainty and coordinated delivery, that could rise to 17,000 jobs — more than a four‑fold increase.

The full HEA report is available here.