US +1800 764 0366 | Europe & Middle East +44 (0)115 980 3800 | Asia-Pacific: +61 2 7227 5369

Support item:

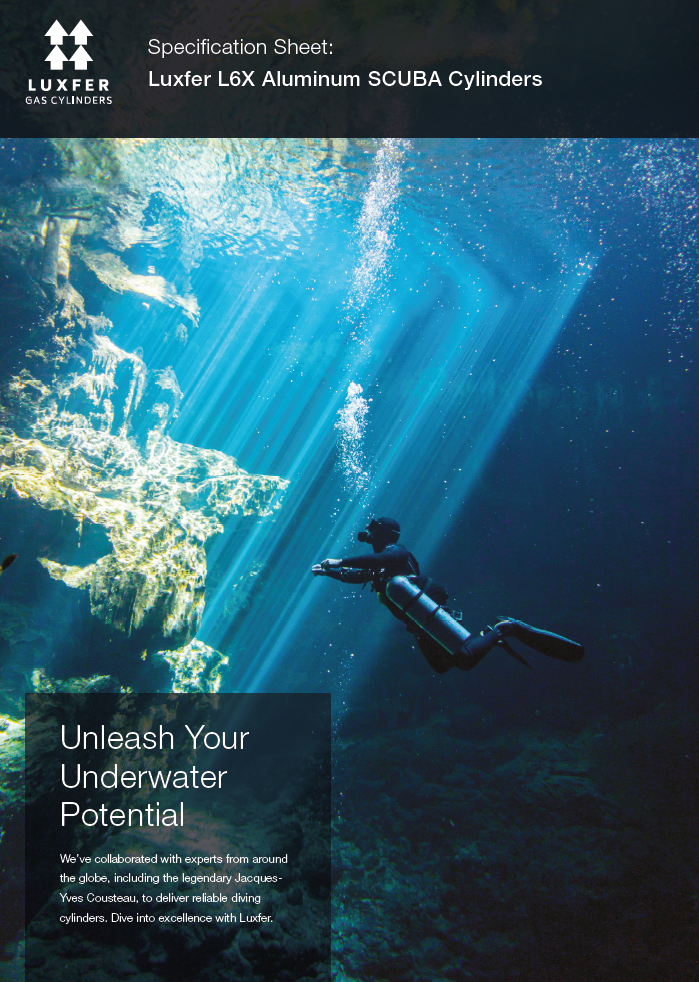

Luxfer L6X Aluminum SCUBA Cylinders

A high-quality cylinder is essential for a comfortable and worry-free dive. Luxfer, a leading provider of SCUBA cylinders, has over 1 million cylinders in use worldwide. We pioneered our first L6X Aluminum SCUBA cylinder with Jacques-Yves Cousteau, revolutionizing the market.