US & Asia-Pacific +1 800 764 0366 | Europe & Middle East +44 (0)115 980 3800

Support Items

Support Items

Support item:

Industrial Gas Cylinder – Care and Maintenance

Support item:

Luxfer Hoop-Wrapped Cylinder User Manual

Luxfer hoop-wrapped carbon or aramid fibre gas cylindersGuide for the use, maintenance and periodic inspection in Europe of hoop-wrapped Luxfer cylinders (carbon or aramid fibre)

Support item:

Modern Slavery Act 2015

This statement is made pursuant to Section 54 of the Modern Slavery Act 2015 and sets out the steps taken by Luxfer and its subsidiaries (“Luxfer”), for financial year ended December 31, 2018, to ensure that slavery and human trafficking is not ongoing within any of the Luxfer’s businesses or supply chains.

Introduction

Luxfer is aware that modern slavery takes various forms, including slavery, servitude, forced labour, child labour and human trafficking, and that it is a global and growing issue. Luxfer has a zero-tolerance approach to modern slavery and is committed to acting ethically and with integrity in all of its business dealings and relationships. Luxfer encourages all stakeholders in its businesses to bring to its attention issues or grievances relating to any potential human rights concerns.

Organisational Structure

Luxfer is a global materials technology company, specialising in the design, manufacture and supply of high-performance materials, components and high-pressure gas-containment devices for healthcare, environmental, protection and speciality end-markets. Headquartered in Manchester, UK, Luxfer has a global presence employing over 1,600 staff and operating from twenty manufacturingplants plants based in seven countries. In 2018 our total revenue was approximately $487 million.

Luxfer is organised into five business units:

- Luxfer Gas Cylinders;

- Luxfer Graphic Arts;

- Luxfer Magtech;

- Luxfer MEL Technologies; and

- Luxfer Superform.

Supply Chain

Luxfer has a very broad-based and complex supply chain, which includes the sourcing of primary magnesium, aluminium log and alloys, zirconium sand, rare earth metals, carbon fibre and other speciality chemical compounds and intermediaries. Luxfer is aware that multiple risks accompany such a complex supply chain, including the possibility that modern slavery may be taking place.

Relevant Policies

Luxfer’s internal policies include:

- Code of Ethics and Business Conduct, which sets out Luxfer’s principles, requirements and expectations in relation to the protection of human rights in all areas of its business; and

- Whistleblowing Policy, aimed principally at Luxfer employees but also available to others working in the Luxfer supply chains, which encourages the reporting of any wrongdoing which potentially involves human rights violations, including modern slavery. All reports will be fully investigated and remedial actions taken as appropriate.

Due Diligence and Audit of Suppliers

Businesses within Luxfer operate a supplier selection process and have considerable knowledge and understanding of many of the major suppliers, with whom they have a close, long standing business relationship. While Luxfer sources a significant portion of its material and services from European and North American based suppliers, it is understood that some of the goods and services that are purchased, and the countries from which they are sourced, may carry a greater risk.

As part of Luxfer’s ongoing commitment to identify and mitigate the risk of modern slavery in its supply chains, the following steps will continue to be undertaken:

- Audits of new and existing suppliers and manufacturing sites by Luxfer employees;

- Contractual terms with suppliers that include prohibitions on modern slavery; and

- Continued protection of whistleblowers in accordance with the Luxfer Whistleblowing Policy.

In order to ensure the adequacy of the actions being undertaken by Luxfer, there has been an audit of the procurement strategy for each business unit and the implementation of a company-wide process specifically centred around taking steps to ensure Luxfer suppliers are compliant with expected ethical standards.

In undertaking these audits, examples of best practice have been highlighted and communicated throughout Luxfer to encourage the continual improvement of standards. This has included regular audits of supplier sites to ensure compliance with ethical standards reported and outlining any areas for improvement.

This is an ongoing process and Luxfer will continue to review supplier’s practices and their own policies to ensure the future commitment of Luxfer and its suppliers.

Training

Luxfer will continue to provide appropriate training to its employees to ensure a high level of awareness and understanding of the risks and implications of modern slavery in all areas of it business, including its supply chains.

Support item:

2018 Gender pay gap report

At Luxfer Gas Cylinders Limited, we recognise the value in diversity as a key differentiator. As such, we are committed to actively and aggressively reducing our gender pay gap. Below is a PDF containing the 2018 Gender Pay Gap report for Luxfer Gas Cylinders.

Support item:

Luxfer does not require or recommend eddy-current

Luxfer Gas Cylinders has received questions from cylinder inspectors and users about whether it is necessary to use eddy-current devices to test Luxfer scuba cylinders made from aluminum alloy 6061 (AA6061).

Eddy-current testing is used to detect sustained-load cracking (SLC) in aluminum alloy cylinders. The majority of Luxfer aluminum alloy cylinders in service today are made from Luxfer AA6061 alloy, which is not susceptible to SLC.

For all scuba cylinders made from Luxfer AA6061, the Luxfer manufacturer’s requirement is that cylinders conform to regulatory requirements for periodic inspection and testing in the countries in which cylinders are being used. Luxfer does not require or recommend eddy-current testing of these AA6061 cylinders.

Support item:

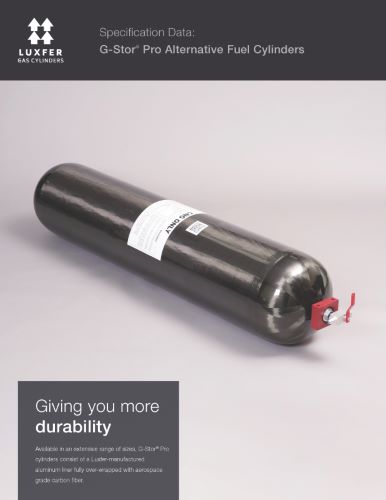

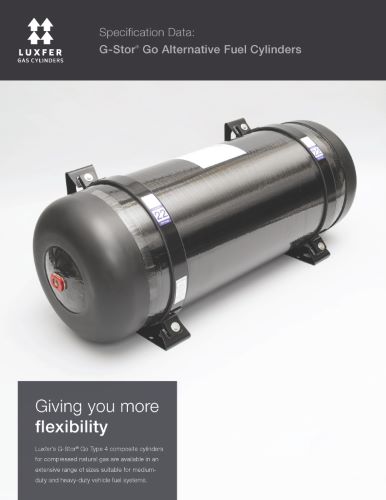

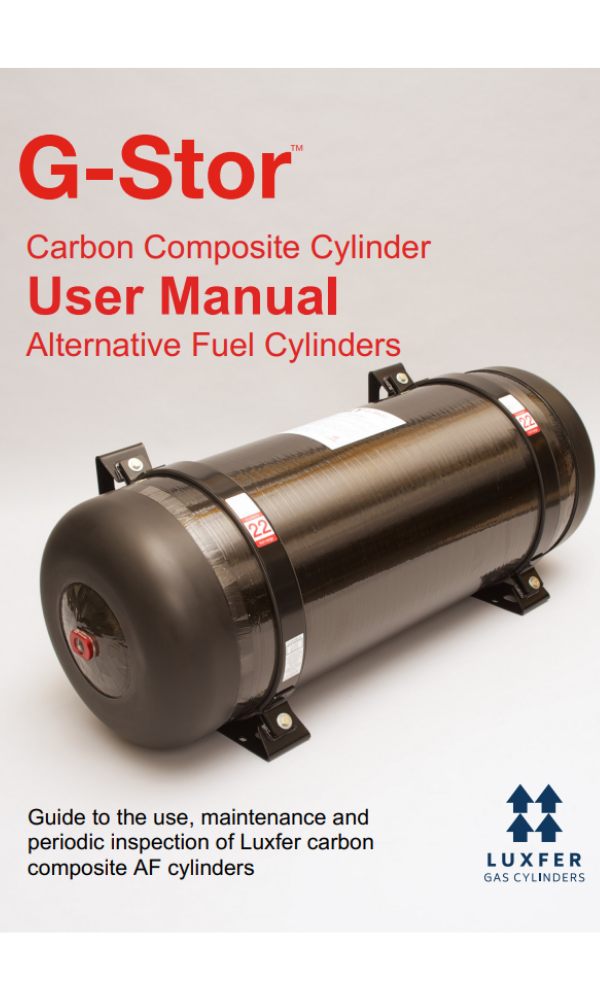

G-Stor™ carbon composite cylinder user manual Al

Guide to the use, maintenance and periodic inspection of Luxfer G-Stor™ carbon composite Alternative Fuel cylinders.

Support item:

OTV Technical Bulletin

Torques greater than the maximum specified are unnecessary and can damage the valve and in extreme over-torque cases might create unsafe conditions.

High over-torques can split the knob into 2 or 3 pieces. A cracked or split knob does not affect valve sealing; however, it indicates excessive torque applied to the knob. Replace a cracked or split knob immediately.

Please see the attached PDF file for further support.