US & Asia-Pacific +1 800 764 0366 | Europe & Middle East +44 (0)115 980 3800

By switching to hydrogen fuel cells on buses and coaches, we can significantly reduce the carbon footprint of the transportation industry, which will empower nations and local authorities to meet their environmental goals.

Hydrogen powered buses rival diesel and petrol fuelled buses in terms of performance and range, while massively cutting harmful emissions. Hydrogen fuel systems replace petrol and diesel engines to create automotive power while only producing water vapour as a by-product.

What is a hydrogen fuel cell bus?

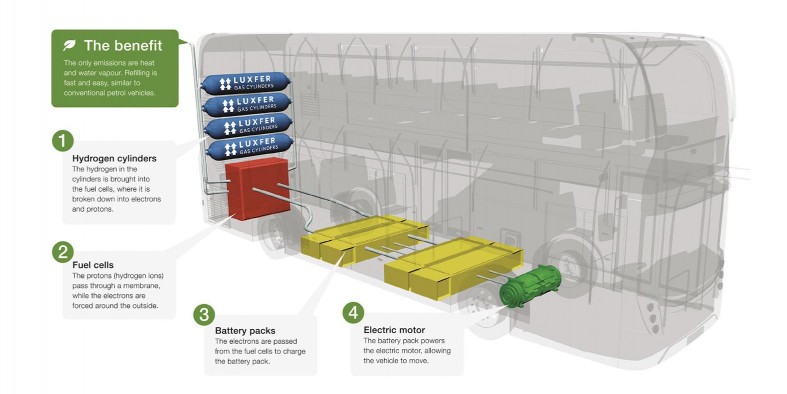

Hydrogen powered buses work by converting hydrogen molecules into energy to charge a battery pack which powers an electric motor.

A hydrogen fuel system is made up of the following on-board components:

- Hydrogen cylinders

- Fuel cells

- Battery pack

- Electric motor

Here’s how the system works.

- The hydrogen is brought from the cylinders into the fuel cells, where the hydrogen molecules are broken down into electrons and protons.

- In the fuel cells, the protons (hydrogen ions) pass through a membrane, while the electrons are forced around the outside. The only by-product of this process is water vapour.

- The electrons are passed from the fuel cells to charge the battery pack.

- The battery pack powers the electric motor, enabling the vehicle to move.

The efficient design of the system means that significant power can be produced while only harmless water vapour is emitted from the exhaust. This makes the hydrogen fuel system one of the cleanest automotive fuel systems available.

How is hydrogen produced?

While hydrogen powered vehicles are essentially zero emission, the hydrogen production process is not necessarily so. The amount of fossil fuel emissions created by the hydrogen production process depends on the type of process being used.

In 2020, it was reported that 95% of the world’s hydrogen was produced using the steam methane reforming process (SMR). In this method, natural gas reacts with steam at a high temperature to produce hydrogen and carbon monoxide. The carbon monoxide is then passed into a secondary reaction to create more hydrogen and carbon dioxide.

This method requires fossil fuels and can potentially be costly in terms of carbon emissions.

The good news is that there are other, cleaner methods of producing hydrogen, such as the electrolysis of water. This process can be made sustainable – for example, by harnessing electricity from a solar or wind farm – in order to create a zero-emission supply chain.

The goal is to continue to innovate this production process so that all hydrogen production plants are working with net zero emissions in the future.

Are hydrogen buses slower than traditional buses?

Hydrogen fuel cell buses can have the same range and speed as a petrol or diesel powered bus. This isn’t limited to single decker vehicles – this method can also be used to power hydrogen double decker buses. In fact, England’s first fleet of hydrogen powered double deckers was launched in London in June 2021.

On average, a hydrogen bus can travel 350 – 400 miles on a single tank of fuel.

This means that passengers can expect their journey on a hydrogen bus to take no longer than it would on a petrol or diesel powered bus. The journey will likely be more pleasant, too, as the ride is smoother and quieter.

A hydrogen fuel bus can be refuelled quickly and easily on the go. On average, a hydrogen bus takes only 3-5 minutes to refuel. As hydrogen refuelling infrastructure expands, it is becoming increasingly more convenient to refuel hydrogen buses.

Are hydrogen buses safe?

While there are always risks when handling combustible fuels, hydrogen is safe to use for public transportation when guidelines are properly followed.

Petrol and diesel are far more flammable than hydrogen. This is because spilled petrol and diesel pool on the ground, creating a highly flammable surface. Fires caused by the ignition of these fuels can burn at high temperatures for a long time.

Hydrogen, on the other hand, disperses rapidly if spilled, rising up into the air at 72 kilometres per hour. This means that the flammable fuel is quickly dispersed into the atmosphere reducing the chance of it igniting.

If the hydrogen does ignite, it produces flames that generate a low radiant heat and the fire should quickly burn out. This is due to the absence of carbon.

Hydrogen is a colourless, odourless gas, which means it can be hard to spot a spill. However, hydrogen refuelling stations operate strict procedures to prevent accidents, including the use of earthing cables which prevent sparks caused by static electricity.

Buses are also fitted with hydrogen detectors that immediately notify operators should a spill occur.

Overall, hydrogen is considerably safer than petrol and diesel alternatives. Although it is a relatively new fuel source, safety is a high priority in all research and development in this field.

What’s the future of the hydrogen fuel project?

“Hydrogen has an important part to play in the decarbonisation of transport and the reduction in CO2 levels that we need to reach to ensure a net zero future.”

Wrightbus chairman, Jo Bamford.

The Mayor of London, Sadiq Khan, has pledged that from now on all new double decker buses in London will be hydrogen, hybrid or electric. The goal for London is to transform the entire fleet of 9,200 single and double decker buses into zero emission vehicles by 2037.

In March 2021 the UK government announced it will be pouring £54 million into emissions-cutting trucks and buses, with the goal of saving 45 million tonnes of carbon emissions. That’s around the same amount of emissions produced by 1.8 million cars over their lifetimes. The initiative is also set to create nearly 10,000 jobs.

From this budget, £11 million will go to the development of hydrogen buses.

What part does Luxfer play?

Our purpose is to provide bus companies with a cleaner and more efficient alternative to fossil fuels to keep vehicles on the road for longer and reduce operating costs.

We’ve been working closely with manufacturers like Wrightbus to supply hydrogen cylinders for buses. Our collaborative approach saw the launch of the world’s first hydrogen bus in Aberdeen in January 2021.

Hydrogen buses are being introduced in many towns and cities across Europe, and although this technology may be new to most passengers, we have been supplying storage solutions for alternative fuel vehicles for over 30 years.

At Luxfer we provide a full design and build for the complete fuel storage solution, including our lightweight G-Stor H2 Type 3 aluminium lined cylinder wrapped in aerospace-grade carbon fibre, piping, regulation systems and ready-to-fit frames.

All systems are certified to the latest regulations, giving peace of mind to passengers, bus companies and operators alike.

By designing a bespoke system to fit each bus, Luxfer works with manufacturers to provide the optimum balance between capacity and weight. Our system ensures that a bus can complete a full shift without needing to refuel, whilst keeping weight to a minimum.

We believe that hydrogen fuel cells are the best green alternative to petrol and diesel for bus systems, giving the equivalent power, performance and range while dramatically cutting emissions. These systems will help restore clean air in cities and significantly reduce the carbon footprint of the transport industry. We’re excited and inspired to be part of this ever advancing movement.