US & Asia-Pacific +1 800 764 0366 | Europe & Middle East +44 (0)115 980 3800

Hydrogen salt spreaders in Scotland – equipped with Luxfer G-Stor® Pro Bundles – help deliver up to 28% reduction in carbon emissions in landmark Balfour Beatty project

In a powerful demonstration of how partnerships are paving the way to net zero, Luxfer Gas Cylinders, together with hydrogen specialists PlusZero Power have supported Balfour Beatty adopting green hydrogen as an alternative low carbon fuel.

Retrofitting heavy vehicles for hydrogen power

At the heart of the collaboration was a trial retrofitting three HGVs – two gritters and one Impact Protection vehicle – with dual fuel hybrid hydrogen technology. They operated during the 2024/25 winter on Scotland’s M77 GSO network.

PlusZero Power – the company responsible for delivering green hydrogen to Balfour Beatty’s depot south of Glasgow – commissioned Luxfer’s alternative fuel team to help. This resulted in its innovative multiple cylinder package (MCP), the G-Stor® Pro Bundle, providing the vital hydrogen storage and transport capability for the dual-fuel fleet.

The trial supported Balfour Beatty’s move to alternative low carbon fuel as part of its wider decarbonisation strategy. Hydrogen technology was of particular interest for larger, heavier vehicles and plant, which are unlikely to be able to run off from a battery due to the power demands of the equipment and the lack of grid capacity.

Balfour Beatty sees retrofit as a good way to test the technology and learn about hydrogen usage, whilst still allowing its vehicles to run fully on diesel if required. This approach also offers the opportunity for the hydrogen industry in Scotland to grow steadily yet rapidly, allowing meaningful reductions to be made while hybrid or fully hydrogen vehicles and plant become available through the supply chain.

Road-testing a bespoke on-site mobile refuelling solution

Benefits of the trial included a 28% reduction in vehicle emissions during a critical winter maintenance period. And it also delivered valuable insights into the practical deployment of hydrogen technology on a live, constrained road operation and maintenance depot – from storage efficiency and safety, to logistical design and commercial viability.

For PlusZero Power, the project aligns with its own mission to enable practical decarbonisation for its clients – drawing on the decades of experience from Luxfer engineers for a hydrogen storage solution fit for purpose.

“Balfour Beatty needed to trial a lower-risk, lower-emission solution using hydrogen-diesel dual fuel vehicles,” explains David Amos from PlusZero Power. “The vehicles can reduce carbon emissions by up to 30% compared to diesel alone. They’re a great transitional technology for companies not yet ready to go fully electric or hydrogen.”

To fuel the trial, PlusZero Power supplied green hydrogen produced by Aberdeen City Council’s ACHES facility and delivered it to site using Luxfer’s G-Stor® Pro Bundle – a composite cylinder pack offering a significantly higher gas capacity than the steel manifold packs previously used.

Smarter gas storage equals safer construction sites

Gas storage and site safety were paramount for Balfour Beatty. “Using the Luxfer G-Stor® Pro Bundle meant we could deliver much more hydrogen with a lower total weight and smaller footprint,” says David. “Each pack carried 44kg of hydrogen compared to just 17kg in steel options – all while being 400kg lighter. That had a huge positive impact on site logistics, frequency of deliveries and overall safety.”

The G-Stor® Pro Bundles’ composite build and horizontal cylinder layout offered further advantages. “It’s a lower-profile unit, which is more stable in transport and on-site,” David adds. “And fewer vehicle movements on site means reduced risk – something Balfour Beatty was very conscious of.”

The bundles from Luxfer Gas Cylinders were connected to a portable hydrogen refueller, which then filled the dual-fuel HGVs. “The system worked well overall,” says David. “And it has been really valuable to gather learnings along the way. With Luxfer, we have a proactive partner who is open to taking feedback on board and designing a system that will meet the specific needs of the project.

“From the very first gas fill, the Luxfer team was on-site, observing the process. They immediately identified that the valve placement could be improved, and set to work to optimise it. That responsiveness is exactly what you want in a partner. Luxfer’s R&D team clearly values real-world insights – and that gives us confidence as a customer.”

This specific trial – which is part of Balfour Beatty’s M77 Hydrogen Project – has now concluded, with the full findings published here.

Balfour Beatty intends to use the vehicles again for the 2025/26 winter season, to allow more intense testing of the equipment and further data collection.

Angela Pllu, Senior Environmental Sustainability Manager at Balfour Beatty, explains: “We are keen to develop our learning and understanding about hydrogen. Solutions like the G-Stor® bundles really help make hydrogen a more feasible option for our tightly constrained sites.”

Building the hydrogen ecosystem, together

The relationship between PlusZero Power and Luxfer Gas Cylinders is set to grow too.

“We’re already in discussions about two major construction projects, including one in the Western Isles of Scotland,” reveals David. “Those sites will have much higher hydrogen demand, so we’re looking at Luxfer’s larger G-Stor® Hydrosphere solution. We’ll need 20-foot or even 40-foot MEGCs to meet daily power needs, and Luxfer has the technology to do that.”

While financing such infrastructure can present a challenge, Luxfer’s G-Stor® hydrogen storage portfolio offers flexibility. David adds: “It was advantageous that Luxfer supported us with short-term rental options for the G-Stor® Pro Bundle and they are working hard to create viable leasing models for larger assets. That commercial agility – paired with their willingness to collaborate and adapt – makes them a standout supplier.”

Projects of this nature form part of a broader shift across the UK construction sector. With government policy, industrial targets, and client demands all driving decarbonisation, hydrogen is rapidly becoming a serious contender for temporary power and vehicle fuel on construction sites.

“Balfour Beatty – and other major firms in the industry – are investing time and money into understanding hydrogen’s potential,” says David. “From gritters to diggers, refuelling to remote generation, a construction-site hydrogen ecosystem is emerging. The sector will need safe, efficient storage – and that’s where Luxfer comes in.”

As for why PlusZero Power sees Luxfer as a long-term partner? “It’s not just about the product – though quality matters, of course,” concludes David. “It’s the relationship. They’re not the cheapest, but they are the most collaborative and customer focused. And when we’re talking about assets that could cost millions over the coming years, that makes all the difference.”

Key results of the trial with Balfour Beatty

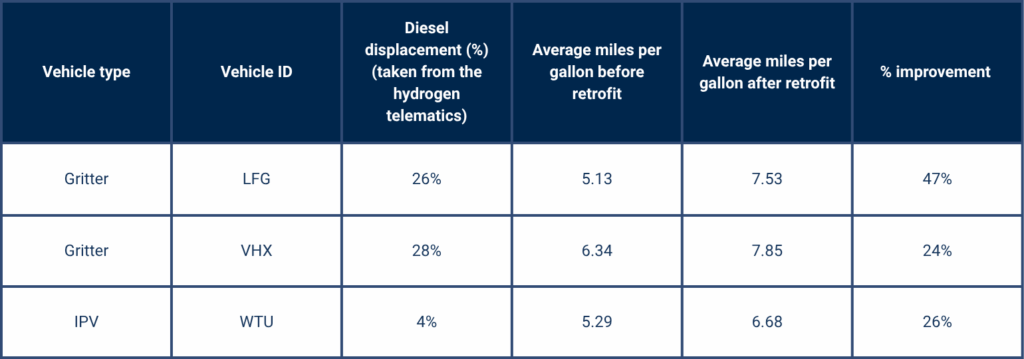

The key performance results from the trial are shown in the table below:

While the IPV appeared to use relatively low rates of hydrogen, this still had a good impact in the overall efficiency of the vehicle, although more intense trials are required during winter 2025/26 to understand if this is the case.

Enabling hydrogen into the future

Luxfer Gas Cylinders Europe Vice President and General Manager, Mark Lawday, is conscious of the challenges faced by operators seeking to use the clean fuel, and the projected demand for clean hydrogen by 2030, estimated at 12 to 18 metric tonnes per year globally based on current pipeline of publicly announced projects.

“The takeaway is that with such increased anticipated volumes of hydrogen production, transporting the gas to where it’s needed – safely, cost effectively and efficiently – is fundamental to the entire ecosystem” said Mark. “And, with the G-Stor® portfolio, Luxfer Gas Cylinders is pioneering solutions that advance hydrogen storage capabilities and enable clients to harness hydrogen’s potential.”

Find out how our G-Stor® Pro Bundles can help to power your green projects here